|

|

|

|

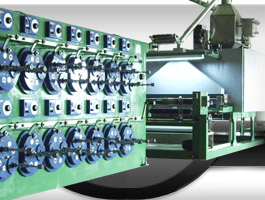

KH-- HE / HC WIRE ENAMELLING EQUIPMENT

KON-HO KH-HE/HC type enamelling system is purposely designed to be

most suited for small-quantity production or enamel coated super-fone wires. with its excellent

fild-proven performance and hignificant energy saving benefit, this completly new model has now been

highly praised by a group of foreseers who

had made their adquate selection several years before.

The construction of the oven body has been properly

designed for efficiently utilizing the latent heat of high temperature gas which is generated by

oxidizing combustion, a induced reaction with the aid of the platinum group catalyst provided in the

exhaust gas hood.The fesdh air supplied by blower, before to be fed into the enamelling oven, is

heated by the high efficiency heat exchanger which is incorporated ib the hood.

|

| |

|

|

| |

|

MAIN OUTSTANDING FEATURES: MAIN OUTSTANDING FEATURES:

- SIMPLE OPERATION:

By once correct setting only, The air charging mechanism of type KH-HE/HC oven can accurately maintain

the enamelling process under stable and safe condition. Thos guarantees the us an advantage of

obtaining quality control at a high level.

- HOT-AIR SYSTEM:

inorder to improve the former out-of -date type oven ventilation system (type CSC system), type

KH-HE/HC enamelling oven uses a moderate hot air system. A precisely conteolled amount of fresh air

that heated in the heat exchanger is continuously forced into the oven b blower through the oven

inlet.As a resuit. the effetive oven length is now longer then that of csc type oren, and coupled with

the advantage of hot air effect, the enamelling wire feeding speed is thus enormously sped up.

- LESS ELECTRICITY CONSUMPTON:

Compared with the former CSC thpe enamelling oven. KH-HE/HC thpy oven is more efficient on energy

consumption.

An approximate velue of 50% of electric power cinsumption will be reduced down when type

KH-HE/HC oven instead of thpe CSC oven is used. This will also contribute to the entire wire

enamelling system a total energy saving of about 30%. Combined the above with increeased wire feeding

speed.

the per-unot energy (kwh/kg) cost can be greatly cut down.

- SHORTER HEATING PERIOD:

The time required for heating up to 500℃ in

KH-HE/HC type oven is shortened to 60 minutes, and thus is very suitable for small-out production.

- TYPE KH-HE/HC oven is equipped with color shade adjuslmenl mechanism to solve

the problem of uneven color shade.

- FLEXIBLE VARNISH APPLICATION:

Ordinary type varnish that has been currently used can be applied in this oven. Besides, type

KH-HE/HC oven

can also accmodate the die wiping for high viscosity varnish without any difficulty.

- NEW MODEL DEVICES:

(1)High quality, reliable catalyst as been used, and its life can be expected to be 3

to 4 years if the ordinary varnish unaffected by catalyotic poison is used after-catalyst temperature

is limited under 650℃

(2) With advanced technology, the new model equipment has prevented form wire

vibuation in the increased wirefeed speed. Besides, various problems associated with adhesion inside

the oven have also been successfully dliminated.

(3) A hot air type dryer has been abopted to meet the higher wire feeding

speed., and a stisfactory operation by maintaing the DV value ( wire diameter x feed velocity )

of 25-30 is guaranteed.

(4) The steam generator operating on exhaust gas has been applied to

achieve a furthur saving in electric power consumption.

|

The type KH-HE/HC ovens are available for various systems of different wire size classes.

Regarding this.Kon-Ho Machinery is capable of furnishing each necessary associated equipbent, such as

annealer and take-up machine which are all compatible with the oven and by taking advantages of a

whole system form a single supply source, the highest possible over-all performance will consequently

develope.

|

| |

KON HO

MACHINERY INDUSTRIAL CO., LTD. KON HO

MACHINERY INDUSTRIAL CO., LTD.

No.46, Ln. 473, Sec. 2, Hezun N. Rd., Jhongli City, Taoyuan County 320, Taiwan (R.O.C.)

TEL:886-3-4621997 886-3-4621998

FAX:886-3-4621999

E-mail:

konho@cables-machinery.com

|

|

![]() KON HO

MACHINERY INDUSTRIAL CO., LTD.

KON HO

MACHINERY INDUSTRIAL CO., LTD.